High Precision Die Cutting Machine with CCD auto position system

Optional Mechanism

-

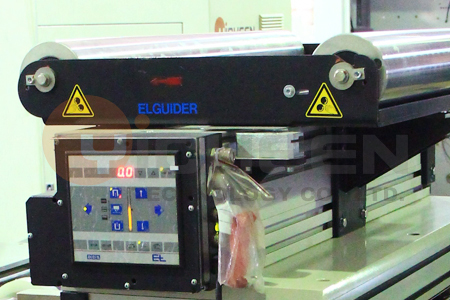

EPC

-

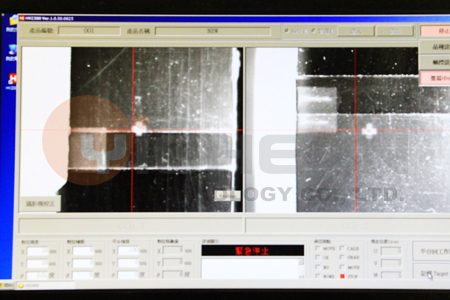

CCD screen

-

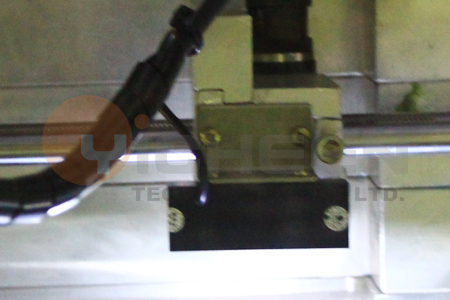

CCD lens

-

Auto movable Stacking

-

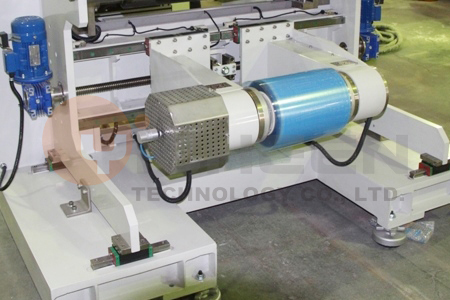

Shaftless device

-

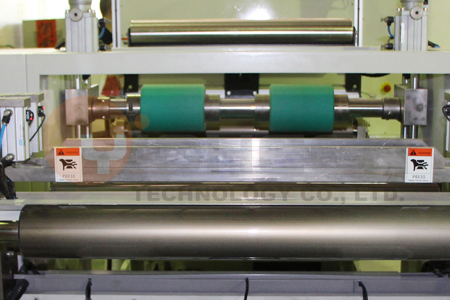

New following material connection platen

Prev

Next

Optional Mechanism

Optional Mechanism:

EPC, CCD screen, CCD lens, Auto movable Stacking, Shaftless device, New following material connection platen

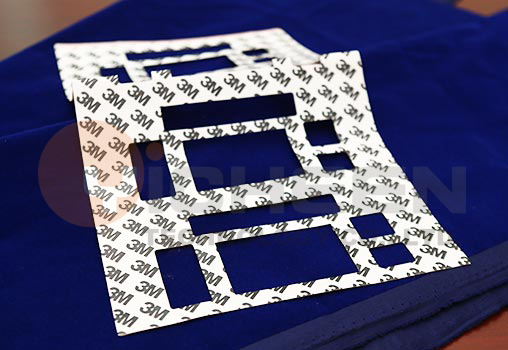

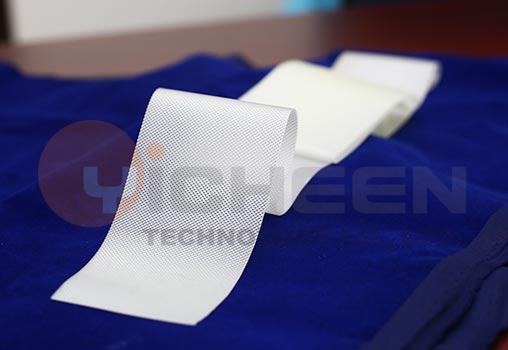

Application:

Optical film, Plastic film, e.g.: ITO, Diffuser, Reflects film, Brightness Enhancement Film (BEF), Soft PCB, Composite material. The material are not cracked while cutting.

Description:

- Max. cutting square is 1500x1500mm special for punching material used in large LCD panel. The machine cutting capability can be reached 80 times/per minute in continuously die cutting running, which the production capability is upgrade 2.5 times than the traditional hydraulic machine.

- PLC computer touch-panel screen control system – clear & easy in operation.

- Full Servo drive type, high speed die cutting, Full die cutting and half die cutting in process.

- Equipped with high precision mold high fine adjustment control, Four-columns can be micro-adjusted independently by computer setting parameter, to save time and to raise the production rate.

- Precision die cut position matching; save time & accurate in die cut mold replacement. Die mold less worn, Long lifetime in use. Also, Optional equipped with knife mold rotative mechanism, it makes the knife mold replaced convenient.

- The knife mold board is available to be replaced in any size in large die cutting machine.

- Equipped with specific transmission mechanism, while the knife mold reaching cutting BDC, it will lower down the cutting speed and make the cutting working staple. No burr or No press indentation occurred on finished product, Makes high yield rate of the production.

- Equipped with safety shelf and safety sensor on each size of machine in order to avoid any dangers while operation.

- Non-hydraulic design, no pollution, low vibration and low noise, to save more than 30% of energy loss comparing with traditional hydraulic machine, best for using in dustless room.

- Optional mechanisms: Rewind stacking system, Unwind system (shelf system or shelfless system).

- Valuable, full-featured equipment, to improve plant ROI.

SPECIFICATIONS

| Model | EDR-0303 | EDR-0505 | EDR-0808 |

| Cutting force | 1 tons Max | 5 tons Max | 5 tons Max |

| Cutting size | W250xL(D)250mm | W450xL(D)450mm | W750xL(D)750mm |

| Material thickness | 0.05~0.3mm | 0.05~0.3mm | 0.05~0.3mm |

| Feeding precision | +/-0.10mm | +/-0.10mm | +/-0.10mm |

| Punching level precision | +/-0.025mm | +/-0.025mm | +/-0.025mm |

| Cutting speed | 80 times/min | 80 times/min | 80 times/min |

| Power consumption | 6Kw | 8Kw | 9Kw |

| Machine size | Approx. L6000 x W2000 x H1680 mm | Approx. L4600 x W2200 x H1900 mm | Approx. L4900 x W2500 x H1900mm |

| Model | EDR-0303 |

| Cutting force | 1 tons Max |

| Cutting size | W250xL(D)250mm |

| Material thickness | 0.05~0.3mm |

| Feeding precision | +/-0.10mm |

| Punching level precision | +/-0.025mm |

| Cutting speed | 80 times/min |

| Power consumption | 6Kw |

| Machine size | Approx. L6000 x W2000 x H1680 mm |

| Model | EDR-0505 |

| Cutting force | 5 tons Max |

| Cutting size | W450xL(D)450mm |

| Material thickness | 0.05~0.3mm |

| Feeding precision | +/-0.10mm |

| Punching level precision | +/-0.025mm |

| Cutting speed | 80 times/min |

| Power consumption | 8Kw |

| Machine size | Approx. L4600 x W2200 x H1900 mm |

| Model | EDR-0808 |

| Cutting force | 5 tons Max |

| Cutting size | W750xL(D)750mm |

| Material thickness | 0.05~0.3mm |

| Feeding precision | +/-0.10mm |

| Punching level precision | +/-0.025mm |

| Cutting speed | 80 times/min |

| Power consumption | 9Kw |

| Machine size | Approx. L4900 x W2500 x H1900mm |

| Model | EDR-1010 | EDR-1212 | EDR-1515 |

| Cutting force | 10 tons Max | 10 tons Max | 10 tons Max |

| Cutting size | W950xL(D)950mm | W1150xL(D)1150mm | W1450xL(D)1450mm |

| Material thickness | 0.05~0.3mm | 0.05~0.3mm | 0.05~0.3mm |

| Feeding precision | +/-0.10mm | +/-0.10mm | +/-0.10mm |

| Punching level precision | +/-0.025mm | +/-0.025mm | +/-0.025mm |

| Cutting speed | 80 times/min | 80 times/min | 80 times/min |

| Power consumption | 24Kw | 27Kw | 28Kw |

| Machine size | Approx. L5900 x W3000 x H2000 mm | Approx.L6100 x W3200 x H2000 mm | Approx. L6400 x W3500 x H2000 mm |

| Model | EDR-1010 |

| Cutting force | 10 tons Max |

| Cutting size | W950xL(D)950mm |

| Material thickness | 0.05~0.3mm |

| Feeding precision | +/-0.10mm |

| Punching level precision | +/-0.025mm |

| Cutting speed | 80 times/min |

| Power consumption | 24Kw |

| Machine size mobile | Approx. L5900 x W3000 x H2000 mm |

| Model | EDR-1212 |

| Cutting force | 10 tons Max |

| Cutting size | W1150xL(D)1150mm |

| Material thickness | 0.05~0.3mm |

| Feeding precision | +/-0.10mm |

| Punching level precision | +/-0.025mm |

| Cutting speed | 80 times/min |

| Power consumption | 27Kw |

| Machine size mobile | Approx.L6100 x W3200 x H2000 mm |

| Model | EDR-1515 |

| Cutting force | 10 tons Max |

| Cutting size | W1450xL(D)1450mm |

| Material thickness | 0.05~0.3mm |

| Feeding precision | +/-0.10mm |

| Punching level precision | +/-0.025mm |

| Cutting speed | 80 times/min |

| Power consumption | 28Kw |

| Machine size | Approx. L6400 x W3500 x H2000 mm |

Specifications are subject to change without notice for design improvement.

The specification can be designed by customers demand.