High Speed Slitting and Rewinding Machine

-

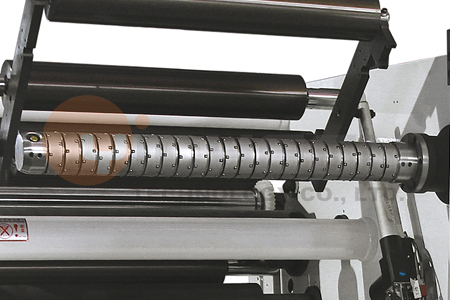

Differential shaft

-

Air Slitter

-

Tension control system

-

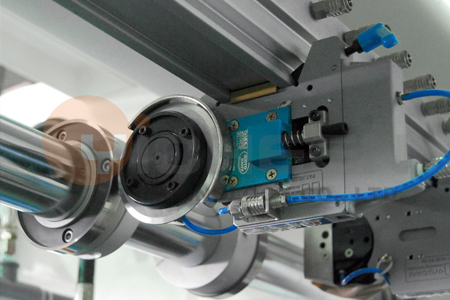

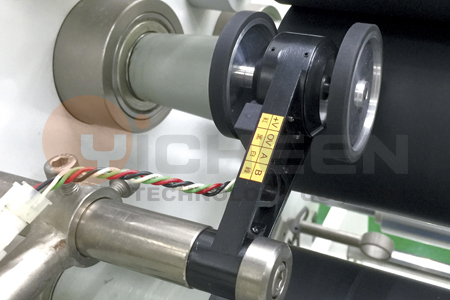

EPC system

-

Shear cutter (up & down)

-

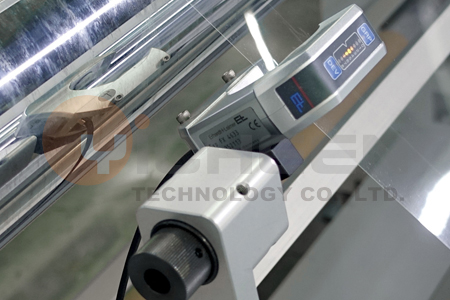

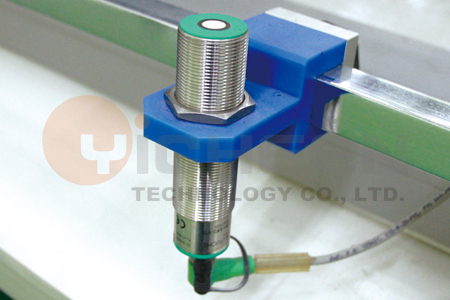

Diameter detector

-

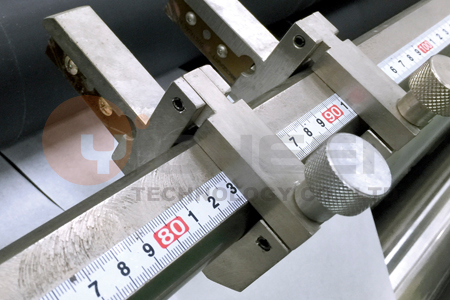

Meter counter

-

Flat blade

-

Air knife

Optional Mechanism:

Differential shaft, Air Slitter,Tension control system, EPC system,Shear cutter (up & down), Diameter detector,Meter counter, Flat blade, Air knife

Application:

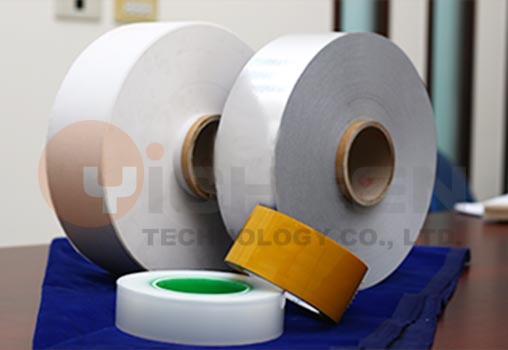

OPP、BOPP、PET、PVC、transfer paper、foil、Non-woven cloth…etc.

The S2 series is widely used for slitting and rewinding materials such as OPP, BOPP, PET, PVC, transfer paper, foil, non-woven fabric, optical films, functional films, labels, and pharmaceutical packaging materials. This wide/narrow-width slitting and rewinding machine is extensively utilized for inspection and rewinding functions due to its versatile wide/narrow-width capabilities.

The wide-width model is a dual-shaft, upper and lower center rewinding slitting machine, specifically designed for slitting various types of composite films. Depending on the process and the rewinding diameter, the standard diameters are 500mm and 600mm.

The narrow-width model is also a dual-shaft, upper and lower center rewinding slitting machine, featuring an integrated structure that provides excellent slitting accuracy and rewinding alignment. The unwind and rewind shafts are designed with a cantilever structure, making it convenient for operators to load (roll) and unload (finished rolls) from the machine's side, especially when working with material carts.

Additionally, to meet the demands of increased production capacity, various levels of automation in drive control, slitting, material loading, and unloading are available as optional configurations.

Description:

- High speed rewind, machine speed is 1~300M/min

- duplex rewinder

- Swing out unwind and rewind air shaft.

- Equipped with automatic tension controller and load cell, tension value digitally display, increase tension control precision and stable.

- Equipped with EPC/LPC position control to ensure accurate slitting position.

- Equipped with razor cutter and circular shear cutter.

- Rewind section equip with diameter-detector to control rewind motor speed.

- Equipped with pneumatic press roller on re-winder to eliminate the air go into rewind film and avoid film slip.

- Full digitally computer control system, equipped with PLC and touch panel system ,error message alarm and indication are displayed on the screen.

SPECIFICATIONS

| Model | S2A |

| Available Width | 0.6M/1.0M/1.3M/1.6M |

| Min. Cutting Diameter | 20mm up |

| Max. Unwind Diameter | 800mm |

| Max. Rewind Diameter | 500mm/600mm |

| Un/Rewind Shaft Diameter | 76.2mm/152mm |

| Machine Speed | 15-300M |

Specifications are subject to change without notice for design improvement.

The specification can be designed by customers demand.