The Importance of Label Die Cutting Machines

If you want to make the most out of your label converting machine, it is important that you understand how it works. There are two main types of label die-cutting machines for label converting : rotary and flatbed.

What is the Label Converting Process ?

The label converting process is a complex system involving many different steps. The label converting processes include label material in long rolls, apply self-adhesive (back side), drying/hot foil stamping, lamination, printing, varnishing, die-cutting(and slitting/sheet cutting). It varies depending on the application of the label, but all converting machines have more than one function as well as multiple parts to them.

What is a Label Die-Cutting Machine ?

Label die-cutting is the process of making custom labels with specific shapes. Labels are typically metal or plastic sheets with printed designs on them. They're used for branding products, identifying contents and helping consumers identify information about their purchases. Because they're often small items with specific requirements, they can be difficult to make without specialized equipment like label cutters and other types of marking tools.

Label die cutting machines are used for different applications in many industries. They could be used for in-mold label, self-adhesive label, sticker, foam, IPO, single or double sided adhesive, post-press materials, etc. The shapes range from simple squares to complex shapes that require multiple dies in order to make them.

Two Main Types of Label Die-Cutting Machines : Rotary and Flatbed

-

Label rotary die-cutting machines

Rotary die-cutting is a form of die cutting that uses a cylindrical die on a rotary press. It moves around and around in a circular motion and has blades to cut out the desired shape around the entirety of the cylinder, which is the most efficient equipment in die-cutting and more beneficial for large-volume production needs.

It is widely used in printing, mobile phones, computers, LCD monitors, digital cameras, LCD backlight, etc. There are two kinds of rotary die-cutting machines : full-totary and semi-rotary. Both of them provide a fast and precise cutting solution for the label printing manufacturing.

- Full-Rotary die-cutting machine : With the full rotary die cutting machine, you will need to change the magnetic cylinder for every repeat size.

- Semi-Rotary die-cutting machine : With the semi-rotary die cutting machine, you only need one magnetic cylinder instead of one for every repeat size. All you need to do is to put the die-cut length in the computer system then you can easily make it run.

The full rotary die-cutting machine is used for high-speed production needs. It provides high efficiency and the speed reaches as high as 300 times per minute. Semi rotary die-cutting machine is used for low-volume production needs. No need to change the magnetic cylinder which saves your cost.

Available additional modules include : varnishing/flexo printing, lamination, hot stamping, cutting, slitting, sheet cutting. With these optional functions, you will get a multifunction die-cutting machine.

-

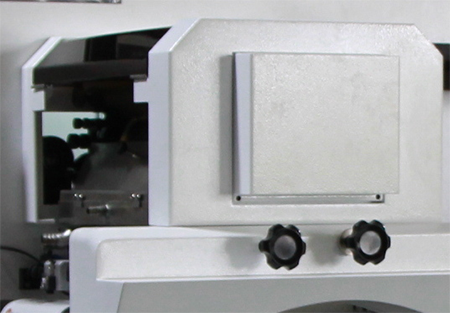

Label flatbed die-cutting machines

Flat-bed die-cutting machine is suitable for large size or small-volume large-variety production. The mold can be replaced in a short time, which saves production cost. The speed can reach 250 times per minute. Additional modules include varnishing/flexo printing, lamination, hot stamping, cutting, slitting and sheet cutting. With these optional functions, you will get a multifunction flatbed die-cutting machine.

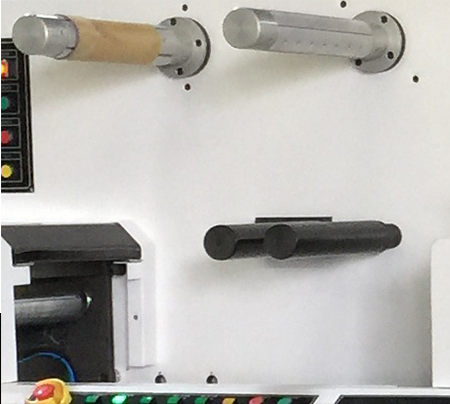

Additional Modules for Die Cutting Machines

Additional modules include varnishing/flexo printing, lamination, cutting, slitting and sheet cutting.

-

1. The modules of varnishing/flexo printing are used when applying raw material for coating.

-

2. The lamination modules are used when applying the film to the surface of raw materials.

-

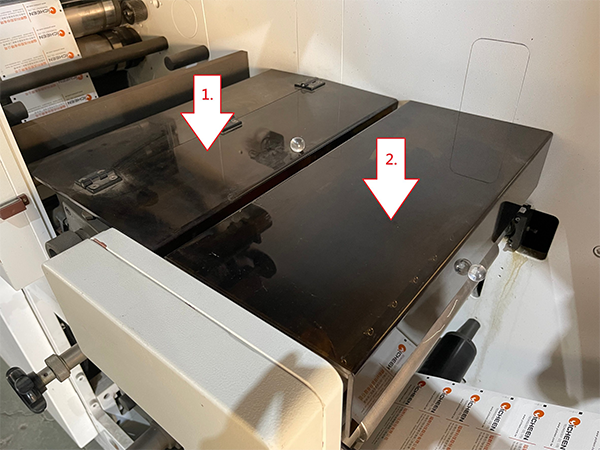

Cold Lamination

-

Hot Lamination

-

Cold Lamination

- 3. The slitting machines are used for cutting large rolls of materials into narrower rolls of materials.

- 4. The sheet cutting machine, also called reel to sheet cutting machine) is designed to convert materials or large rolls to sheets with the needed size.

Leading Label Die Cutting Machine Manufacturer

The best way to learn more about label converting is by talking with experts who have experience designing specific applications. YICHEEN is one of the leading label die cutting machine manufacturers. Our label die cutting machines are used widely in the world and they enjoy high quality and precise tolerance for producing plain labels, stickers for small, medium and large production. There is many optional equipment including flexo printing, laminating, hot stamping, varnishing, and slitting.

To learn more about label converting equipment or label converting lines, please check out our product details, Label converting and finishing system,download specification, or reach out to the team today.